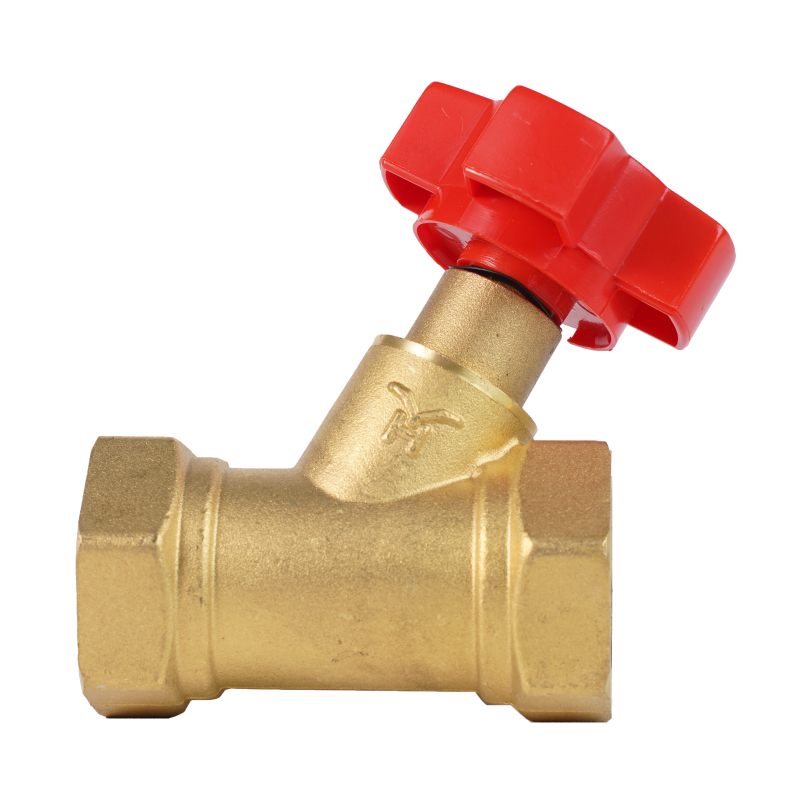

50mm ball valve

The 50mm ball valve stands as a crucial component in fluid control systems, offering reliable and efficient flow management across various industrial applications. This precision-engineered valve features a spherical disc that rotates to control fluid flow, with a 50mm diameter providing optimal flow capacity for medium-sized industrial operations. The valve's design incorporates high-grade stainless steel or brass construction, ensuring durability and resistance to corrosion. Its quarter-turn operation mechanism allows for quick and precise flow control, while the floating ball design ensures tight sealing and minimal leakage. The valve's PTFE seats and seals offer excellent chemical compatibility and temperature resistance, making it suitable for diverse media including water, oil, gas, and various chemical substances. Advanced manufacturing techniques ensure precise tolerances and smooth operation, while the standardized 50mm size makes it compatible with common piping systems. The valve's design also includes features for easy maintenance and long service life, such as blow-out proof stems and adjustable packing glands. For industrial applications, the 50mm ball valve provides essential functions in process control, utility services, and fluid distribution systems, offering reliable performance under varying pressure and temperature conditions.