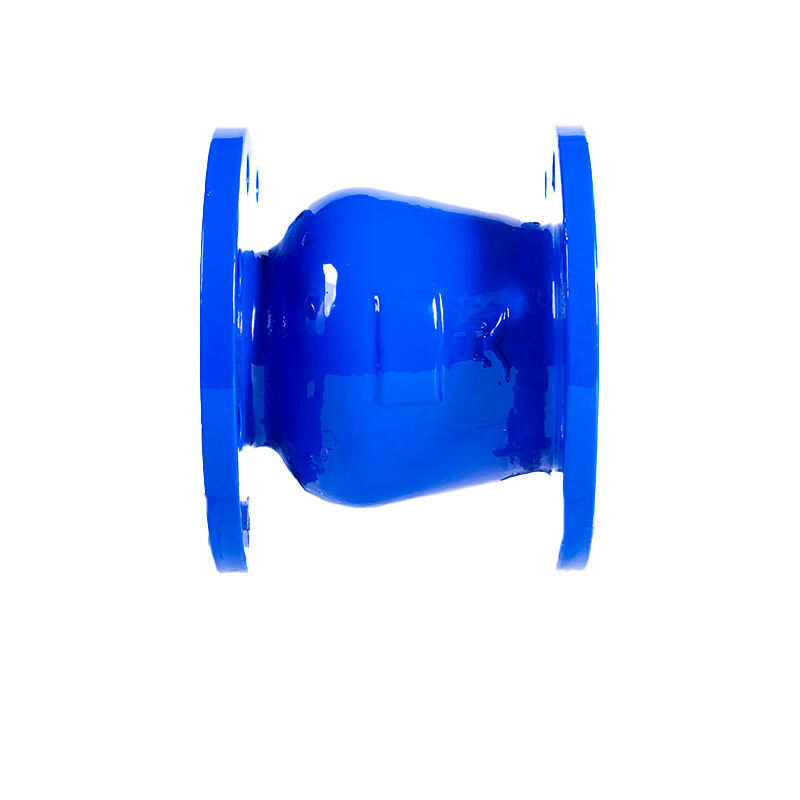

butterfly check valve manufacturer

A butterfly check valve manufacturer specializes in designing and producing high-quality flow control solutions that combine reliability with innovative engineering. These manufacturers employ advanced production techniques and quality control measures to create valves that effectively prevent backflow in various fluid systems. The manufacturing process involves precision engineering, utilizing state-of-the-art CNC machinery and automated testing facilities to ensure consistent product quality. These facilities typically maintain ISO certifications and adhere to international manufacturing standards, including API, ASME, and DIN specifications. The production line encompasses various sizes and pressure ratings, catering to diverse industrial applications from water treatment to chemical processing. The manufacturing process includes comprehensive material selection, from ductile iron to specialized alloys, ensuring optimal performance in different operating conditions. Quality assurance protocols involve multiple inspection points, hydrostatic testing, and material verification to guarantee product integrity. Modern butterfly check valve manufacturers also invest in research and development, continuously improving design features such as seat materials, disc configurations, and coating technologies to enhance valve performance and longevity.