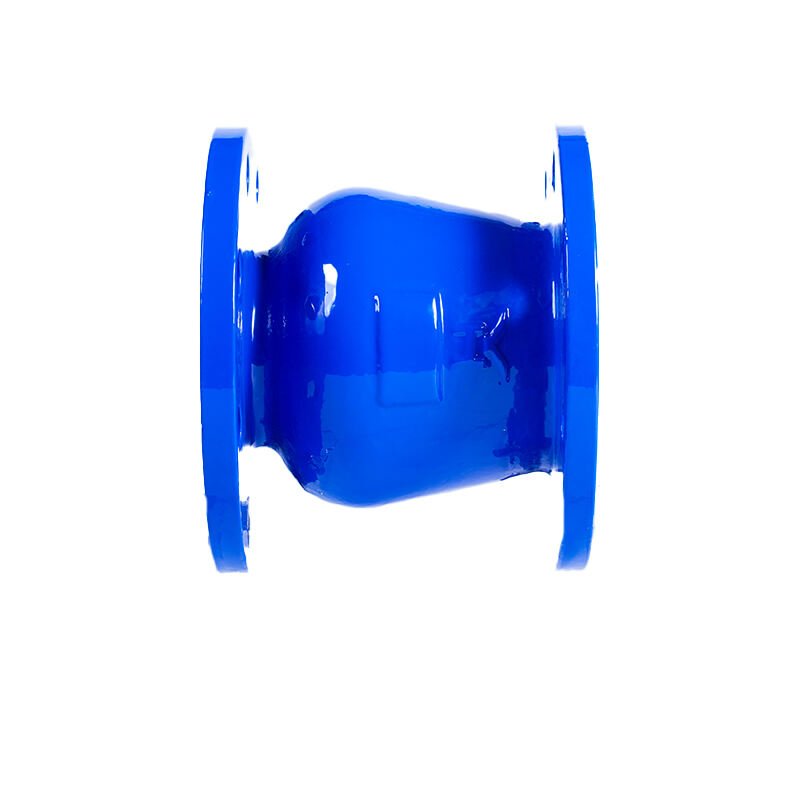

double check backflow preventer

A double check backflow preventer is a critical plumbing safety device designed to protect potable water supplies from contamination or pollution due to backflow. This sophisticated device consists of two independently operating spring-loaded check valves that work in sequence to prevent water from flowing backward into the main water supply. The device is typically installed on water lines where there is a moderate risk of pollution, but no health hazards are present. It operates by maintaining two separate checkpoints, where each valve can fully stop reverse flow independently, providing redundant protection. The main components include two resilient seated check valves, two shutoff valves, and four test cocks for maintenance and testing purposes. These preventers are commonly installed in commercial buildings, irrigation systems, and fire sprinkler systems where the risk of backflow could compromise water quality. The device undergoes mandatory annual testing to ensure proper functionality and compliance with local water regulations. When properly maintained, a double check backflow preventer can provide years of reliable protection for water systems, making it an essential component in modern plumbing infrastructure. The device's robust construction typically features heavy-duty cast iron or bronze housing, ensuring durability and long-term reliability in various environmental conditions.