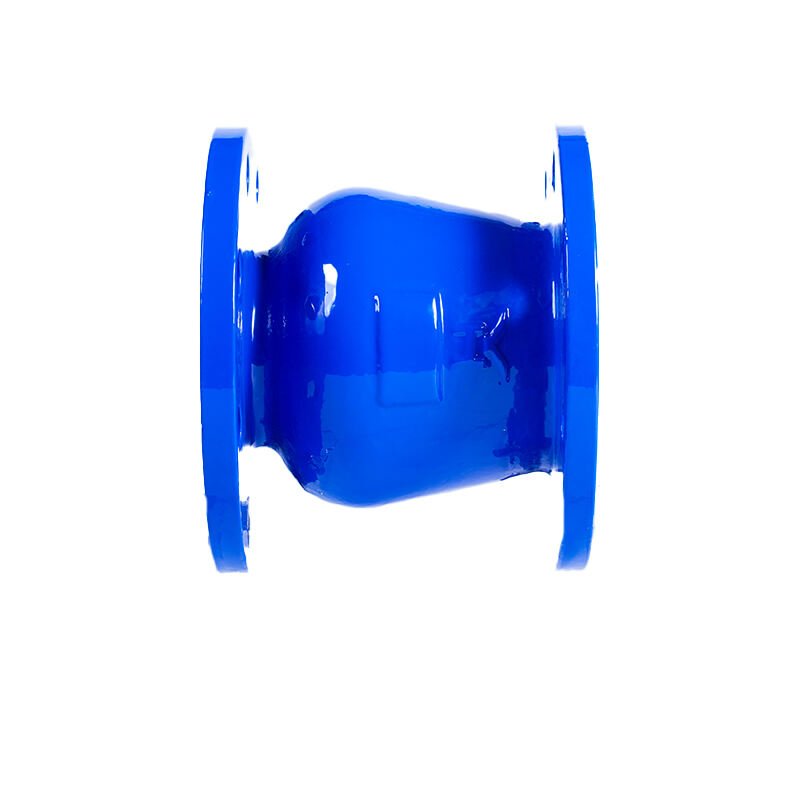

double eccentric butterfly valve

The double eccentric butterfly valve represents a significant advancement in flow control technology, characterized by its innovative design that features two distinct points of eccentricity. This configuration allows the disc to completely disengage from the seat during operation, substantially reducing wear and extending the valve's service life. The first eccentricity positions the stem behind the disc centerline, while the second places the stem offset from the pipe centerline. This dual offset design enables smoother operation and provides superior sealing capabilities compared to traditional concentric butterfly valves. The valve's construction typically incorporates high-grade materials such as stainless steel, carbon steel, or specialized alloys, making it suitable for demanding industrial applications. Operating across a wide temperature range and pressure ratings, these valves excel in applications requiring tight shut-off, frequent cycling, and reliable performance. They are particularly valuable in industries such as water treatment, power generation, chemical processing, and HVAC systems. The double eccentric design significantly reduces the torque required for operation, leading to lower actuator costs and improved energy efficiency. Additionally, the valve's compact design and lighter weight make it an economical choice for large-diameter applications where space and weight considerations are crucial.