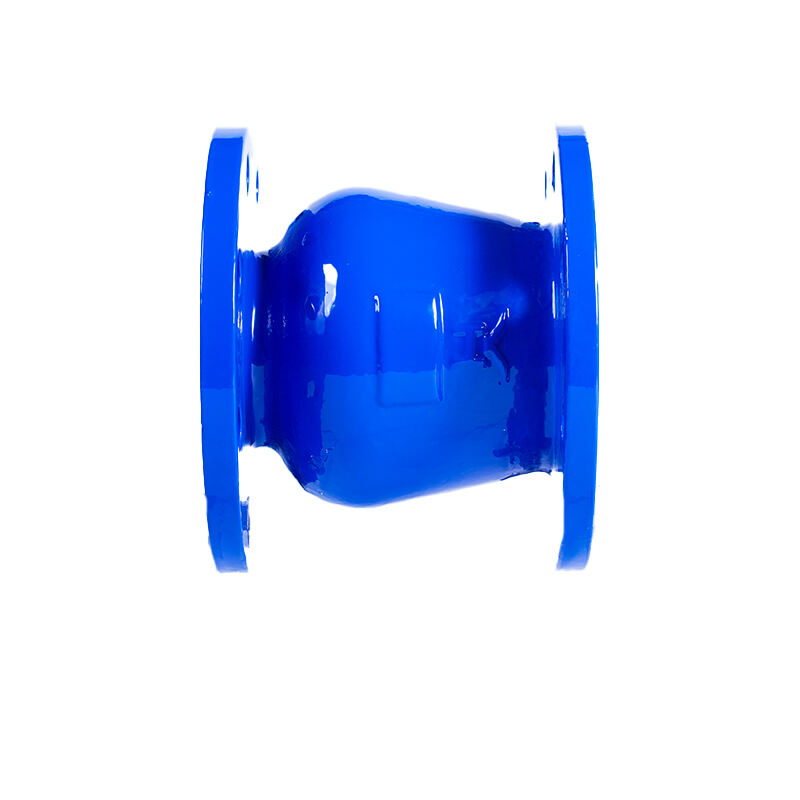

full bore ball valve

A full bore ball valve represents a crucial component in fluid control systems, characterized by its unobstructed flow path that matches the pipe's inner diameter. This innovative design enables unrestricted fluid flow, making it an invaluable addition to various industrial applications. The valve's core mechanism consists of a spherical disc that rotates on its axis, providing precise control over flow regulation. When fully open, the bore aligns perfectly with the pipeline, eliminating pressure drops and flow restrictions typically associated with reduced-bore alternatives. The valve's construction typically features robust materials such as stainless steel, carbon steel, or specialized alloys, ensuring durability and resistance to harsh operating conditions. Modern full bore ball valves incorporate advanced sealing technologies, including reinforced PTFE seats and specialized stem seals, guaranteeing leak-tight performance across diverse pressure ranges. Their quarter-turn operation mechanism simplifies valve actuation, while the full port design facilitates pipeline cleaning and maintenance operations. These valves excel in applications requiring minimal pressure loss, unrestricted flow, and the ability to handle various media, including liquids, gases, and slurries. Their versatility extends to sectors such as oil and gas, chemical processing, water treatment, and power generation, where reliable flow control is paramount.