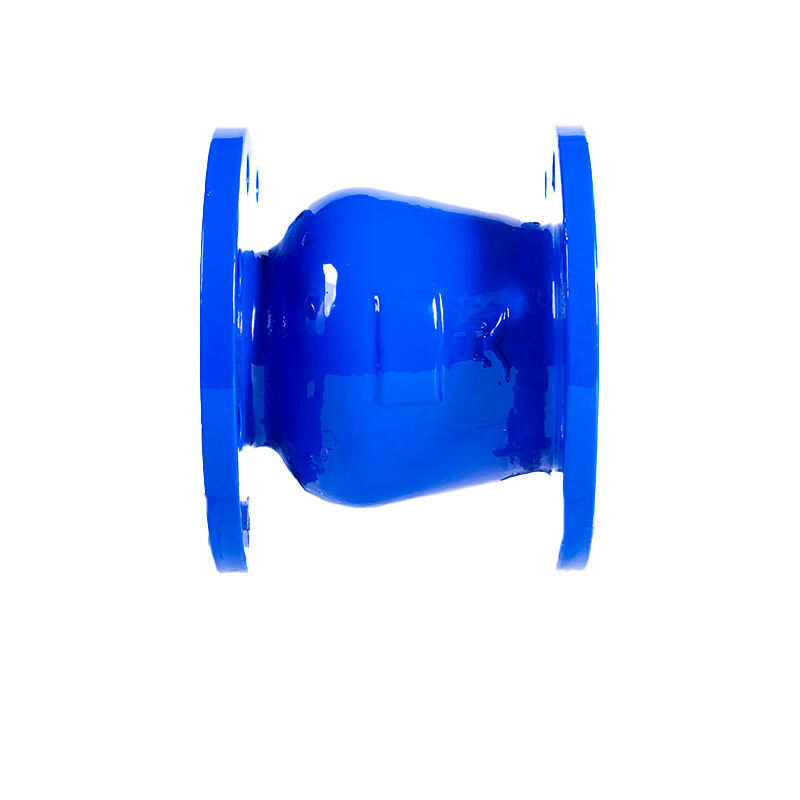

gate valve butterfly

A gate valve butterfly is a critical component in fluid control systems, combining the robust sealing capabilities of traditional gate valves with the quick-acting nature of butterfly valves. This innovative hybrid design features a gate-style sealing mechanism that moves perpendicular to the flow, while incorporating a butterfly disk that rotates to control flow rates. The valve's construction typically includes a durable metal body, resilient seat materials, and precision-engineered sealing surfaces that ensure reliable operation in various industrial applications. Operating at pressures up to 300 psi and temperatures ranging from -20°F to 400°F, these valves excel in applications requiring both tight shutoff and precise flow control. The design allows for bidirectional flow and offers excellent resistance to erosion and corrosion, making it particularly suitable for water treatment facilities, chemical processing plants, and HVAC systems. The valve's unique configuration enables quick operation while maintaining the secure sealing characteristics essential for critical applications. Installation flexibility is enhanced through standardized end connections and multiple actuation options, including manual, electric, and pneumatic operators.