High Quality Large Diameter Ductile Iron Soft Seal Gate Valve

Detail

Basic Info.

Model NO.

HAXZF

Actuator

Manual

Seal Surface

Parallel Gate Valve

Thread Position of Valve Rod

Inside Gate Valve

Usage

Flow Control

Standard

BS, ANSI,En, ISO, GB

Application

Industrial Usage, Water Industrial Usage, Household Usage

Transport Package

Export Standard Package

Specification

DN15-DN2000

Trademark

huhang

Origin

China

Production Capacity

50000PCS/Month

Product Description

1.Overview

Softsealgate valves are widely used in conditions and pipeline for the water supply and drainage and fire system setc. of the building, municipal adm inistration,electric power, metallurgy,chemical industry and other industries,to cutofforconnectpipeline medium .

Our company introduces and refers to European high-tech valve manufacturing standard to produce softsealgate valves,using deform ation compensation effectgenerated by overall encapsulation to achieve a good sealing effect while combining with m anykind of"H uhang"factors to overcome the generalinternaland externalvalve leakage, big torque,rust,shortlife,difficultreplacem entofparts,which also getthe praise and trustfrom users.

"Huhang" as a professional valve design, production, research and developm enterprise, participated in the form ulation and revision work of CJA 216-2013 Soft SealG ate Valve Used for Water Supply and Drainage design standard.

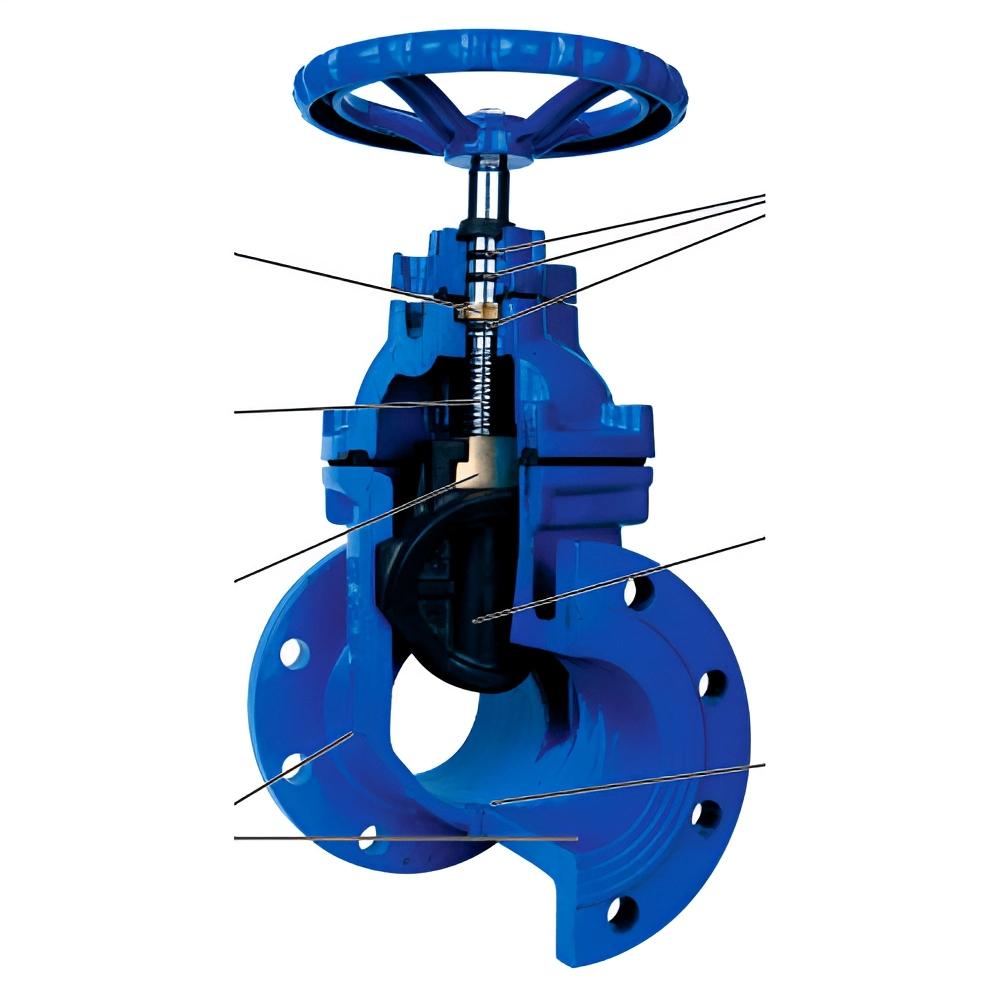

2.Structuralfeatures

3. Application characteristics

3. Application characteristics

1. Anti-leakage design: Gate valve is apatent belonging to our com pany (patent number: 201320837127.X ),designed with cone-shaped self-sealing ring proprietary technology,which make maintenance and replacem entof parts of valve in case ofthe pipeline with pressure (constant water)possible.

2. Coppernut and split collar design: Drivenut and splitcollar use copper alloy design with lower frictional resistance,using larger copper nutthan of those the marketto im prove the service life and reliability ofthe valve.

3. Flat valve seat: The traditional gate valve fails to be closed tightly to generate water leakage due to foreignmatters, such as stone, wood,cement,iron, debris and other deposition in the bottom of the valve groove after washing the pipe with water.Our com pany'sgate valve bottom uses the sam e flat-bottom ed design as the pipeline,which is noteasy to cause debris siltation, so that fluid flow and can autom atically flush valve body cavity flow channel,playing the role ofself-cleaning.

4. Overall encapsulation:The valve gate is made of high-quality rubber for the inside and outside encapsulation.The first-class vulcanization technology in Europe makes the vulcanized valve ensure accurate geom etrical size,and rubber and nodular cast iron valve have strong adhesive force to achieve good flexibility without disengagem ent.

5. Precision castvalve body:Valve body uses precision casting,w ith precise geom etric dim ensioning allow ing the internal valve body to ensure that the valve sealing wellw ith no need of any finishing. Resistance to corrosion:The valve body uses pow der epoxy coating,to preventcorrosion and rustofthe valve body.

6. Backw ard technology: "Huhang" has excellent design team . Its products integrate a variety of "Huhang"elem ents,so the valve has betterquality and longerservice life.

7.No internal and external leakage: In the past, the traditional cast iron gate valve is cracked resulting from foreign objects hit, collision or pressure. As the body uses nodular cast iron, this situation has been greatly reduced.As the valve rod uses the design of three "O" rings for sealing, leakage is prevented,and our company's valve can replace sealring withoutstopping supplying water forconstruction.

8. It can be drunk directly:As the inside and outside of valve body are coated with non-toxic epoxy resin, the surface ofthe gate is com pletely covered with rubber without appearing rustw ater or corrosion phenom enon,and itcan be used for direct drinking water piping system .

9. Casting hand wheel: Hand wheel adopts overall casting, with convex texture (design according to the requirem ents of grasp for palm ), with smooth surface, easy to operate, com fortable, lightw eight and other characteristics,which is more hum anize com pared to traditional gate valve design.

A perfect solution for buried valves, with maintenance-free valves and compact, flexible buried devices.

A perfect solution for buried valves, with maintenance-free valves and compact, flexible buried devices.

· Adopting a design that allows maintenance-free and extends the valve stem's lifespan, buried once, avoiding the huge investment brought by expensive manhole construction, multiple road reconstructions, and valve replacements.

· The extension rods come in adjustable and fixed types. The adjustable type's length can flexibly extend according to the depth of the trench, while the fixed type's length can be micro-adjusted on-site during construction or shortened using a steel saw.

· There are two types of valve boxes: floating and fixed. They can be raised or lowered according to on-site construction and road reconstruction, and can tilt with the road slope (W5) to ensure the smoothness of the road. The floating type is suitable for soft trench soil and easy road settlement, while the fixed type is suitable for hard trench soil, hard road surface, and heavy road loads.

· Valve boxes with a footprint of no more than 200mmx200mm, beautify the urban road environment, withstand rolling without impact, and avoid safety accidents caused by missing manhole covers.

· Optional additional features include theft-proof lock control, opening indication, signal remote transmission, etc.

· Buried gate valves comply with standard CJ/T 262-2007.

Effort-saving type HAXZF-008

Effort-saving type HAXZF-008

· 450-1200, optional with effort-saving device, planetary gear reducer, or bevel gear reducer.

· Vertical installation + effort-saving device: Suitable for valves vertically installed on the surface and operated by handwheel. It can reduce operating torque when the valve opening is 0~5%, with each full opening and closing of the valve constituting one cycle. The effort-saving function needs to be restored after fully opening the valve. Its structure is precise, and proper operation is required to avoid damage.

· Vertical installation + planetary gear reducer: Suitable for valves vertically installed in manholes and operated by T-shaped handles. The reduction ratio is 3~4, and the operating wheel moves in the vertical direction.

· Vertical installation + bevel gear reducer: Suitable for valves vertically installed on the surface and operated by handwheel only from the side. The reduction ratio is 3~6, and the operating wheel moves in the horizontal direction. Optional additional features include opening indication, signal remote transmission, etc.

· Horizontal installation + bevel gear reducer: Suitable for valves installed in shallow manholes, allowing for relatively low operating heights or other installation height restrictions. The reduction ratio is 3~6, and the operating wheel can move in the horizontal or vertical direction. Optional additional features include opening indication, signal remote transmission, etc.

4.Main Connection Dimensions

4.Main Connection Dimensions

Quality and inspection:

Quality and inspection:

Regular check on production line at each working procedure, and one special inspector inspecting the goods in random during the period time of production.regular performance check on finished goods.

Production step:

1.The raw materials are cast or forged and processed into semi-finished products.

2.Processing the semi-products in works shop

3.Assembling the goods

4.Testing the sealing in pressure and checking quality of the goods

5.Package

6.Delivery the goods on time

Package:

1.The pakage standard:inside PVC bag and small box and standard export carton

2.If you have any special requirements pakage,we can pakage as per your artworks.

Primary Competitive Advantages:

1) We have several years of experience in manufacturing various types of valves professionally.

2) Products are of good quality, with reasonable prices.

3) Our style:Promise must be kept and action must be prompt and fruitful.

Our business idea:All for customers and everything from innovation.The size standards can be customized according to your specific requirements. Please feel free to contact us for more details.

Softsealgate valves are widely used in conditions and pipeline for the water supply and drainage and fire system setc. of the building, municipal adm inistration,electric power, metallurgy,chemical industry and other industries,to cutofforconnectpipeline medium .

Our company introduces and refers to European high-tech valve manufacturing standard to produce softsealgate valves,using deform ation compensation effectgenerated by overall encapsulation to achieve a good sealing effect while combining with m anykind of"H uhang"factors to overcome the generalinternaland externalvalve leakage, big torque,rust,shortlife,difficultreplacem entofparts,which also getthe praise and trustfrom users.

"Huhang" as a professional valve design, production, research and developm enterprise, participated in the form ulation and revision work of CJA 216-2013 Soft SealG ate Valve Used for Water Supply and Drainage design standard.

2.Structuralfeatures

3. Application characteristics

3. Application characteristics1. Anti-leakage design: Gate valve is apatent belonging to our com pany (patent number: 201320837127.X ),designed with cone-shaped self-sealing ring proprietary technology,which make maintenance and replacem entof parts of valve in case ofthe pipeline with pressure (constant water)possible.

2. Coppernut and split collar design: Drivenut and splitcollar use copper alloy design with lower frictional resistance,using larger copper nutthan of those the marketto im prove the service life and reliability ofthe valve.

3. Flat valve seat: The traditional gate valve fails to be closed tightly to generate water leakage due to foreignmatters, such as stone, wood,cement,iron, debris and other deposition in the bottom of the valve groove after washing the pipe with water.Our com pany'sgate valve bottom uses the sam e flat-bottom ed design as the pipeline,which is noteasy to cause debris siltation, so that fluid flow and can autom atically flush valve body cavity flow channel,playing the role ofself-cleaning.

4. Overall encapsulation:The valve gate is made of high-quality rubber for the inside and outside encapsulation.The first-class vulcanization technology in Europe makes the vulcanized valve ensure accurate geom etrical size,and rubber and nodular cast iron valve have strong adhesive force to achieve good flexibility without disengagem ent.

5. Precision castvalve body:Valve body uses precision casting,w ith precise geom etric dim ensioning allow ing the internal valve body to ensure that the valve sealing wellw ith no need of any finishing. Resistance to corrosion:The valve body uses pow der epoxy coating,to preventcorrosion and rustofthe valve body.

6. Backw ard technology: "Huhang" has excellent design team . Its products integrate a variety of "Huhang"elem ents,so the valve has betterquality and longerservice life.

7.No internal and external leakage: In the past, the traditional cast iron gate valve is cracked resulting from foreign objects hit, collision or pressure. As the body uses nodular cast iron, this situation has been greatly reduced.As the valve rod uses the design of three "O" rings for sealing, leakage is prevented,and our company's valve can replace sealring withoutstopping supplying water forconstruction.

8. It can be drunk directly:As the inside and outside of valve body are coated with non-toxic epoxy resin, the surface ofthe gate is com pletely covered with rubber without appearing rustw ater or corrosion phenom enon,and itcan be used for direct drinking water piping system .

9. Casting hand wheel: Hand wheel adopts overall casting, with convex texture (design according to the requirem ents of grasp for palm ), with smooth surface, easy to operate, com fortable, lightw eight and other characteristics,which is more hum anize com pared to traditional gate valve design.

A perfect solution for buried valves, with maintenance-free valves and compact, flexible buried devices.

A perfect solution for buried valves, with maintenance-free valves and compact, flexible buried devices.· Adopting a design that allows maintenance-free and extends the valve stem's lifespan, buried once, avoiding the huge investment brought by expensive manhole construction, multiple road reconstructions, and valve replacements.

· The extension rods come in adjustable and fixed types. The adjustable type's length can flexibly extend according to the depth of the trench, while the fixed type's length can be micro-adjusted on-site during construction or shortened using a steel saw.

· There are two types of valve boxes: floating and fixed. They can be raised or lowered according to on-site construction and road reconstruction, and can tilt with the road slope (W5) to ensure the smoothness of the road. The floating type is suitable for soft trench soil and easy road settlement, while the fixed type is suitable for hard trench soil, hard road surface, and heavy road loads.

· Valve boxes with a footprint of no more than 200mmx200mm, beautify the urban road environment, withstand rolling without impact, and avoid safety accidents caused by missing manhole covers.

· Optional additional features include theft-proof lock control, opening indication, signal remote transmission, etc.

· Buried gate valves comply with standard CJ/T 262-2007.

Effort-saving type HAXZF-008

Effort-saving type HAXZF-008· 450-1200, optional with effort-saving device, planetary gear reducer, or bevel gear reducer.

· Vertical installation + effort-saving device: Suitable for valves vertically installed on the surface and operated by handwheel. It can reduce operating torque when the valve opening is 0~5%, with each full opening and closing of the valve constituting one cycle. The effort-saving function needs to be restored after fully opening the valve. Its structure is precise, and proper operation is required to avoid damage.

· Vertical installation + planetary gear reducer: Suitable for valves vertically installed in manholes and operated by T-shaped handles. The reduction ratio is 3~4, and the operating wheel moves in the vertical direction.

· Vertical installation + bevel gear reducer: Suitable for valves vertically installed on the surface and operated by handwheel only from the side. The reduction ratio is 3~6, and the operating wheel moves in the horizontal direction. Optional additional features include opening indication, signal remote transmission, etc.

· Horizontal installation + bevel gear reducer: Suitable for valves installed in shallow manholes, allowing for relatively low operating heights or other installation height restrictions. The reduction ratio is 3~6, and the operating wheel can move in the horizontal or vertical direction. Optional additional features include opening indication, signal remote transmission, etc.

4.Main Connection Dimensions

4.Main Connection Dimensions

Quality and inspection:

Quality and inspection:Regular check on production line at each working procedure, and one special inspector inspecting the goods in random during the period time of production.regular performance check on finished goods.

Production step:

1.The raw materials are cast or forged and processed into semi-finished products.

2.Processing the semi-products in works shop

3.Assembling the goods

4.Testing the sealing in pressure and checking quality of the goods

5.Package

6.Delivery the goods on time

Package:

1.The pakage standard:inside PVC bag and small box and standard export carton

2.If you have any special requirements pakage,we can pakage as per your artworks.

Primary Competitive Advantages:

1) We have several years of experience in manufacturing various types of valves professionally.

2) Products are of good quality, with reasonable prices.

3) Our style:Promise must be kept and action must be prompt and fruitful.

Our business idea:All for customers and everything from innovation.The size standards can be customized according to your specific requirements. Please feel free to contact us for more details.