Home

> Products

> Groove pipe fittings

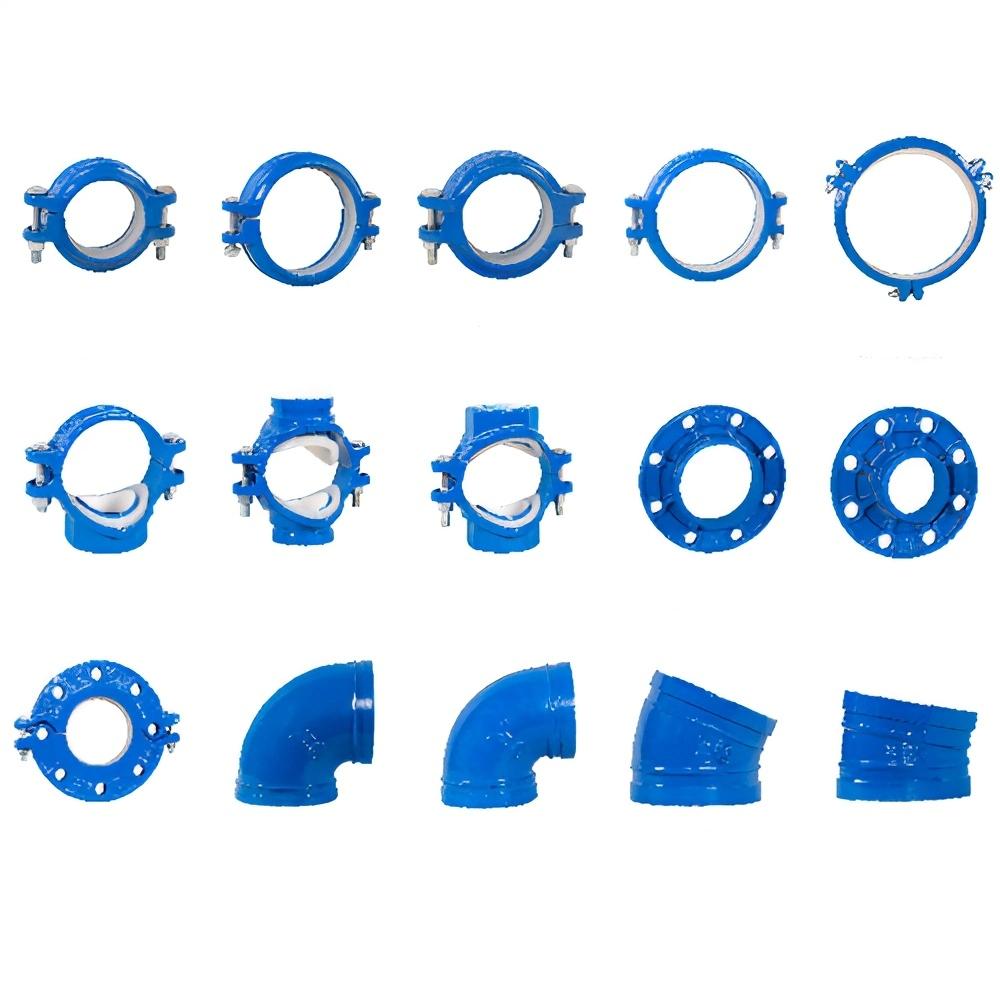

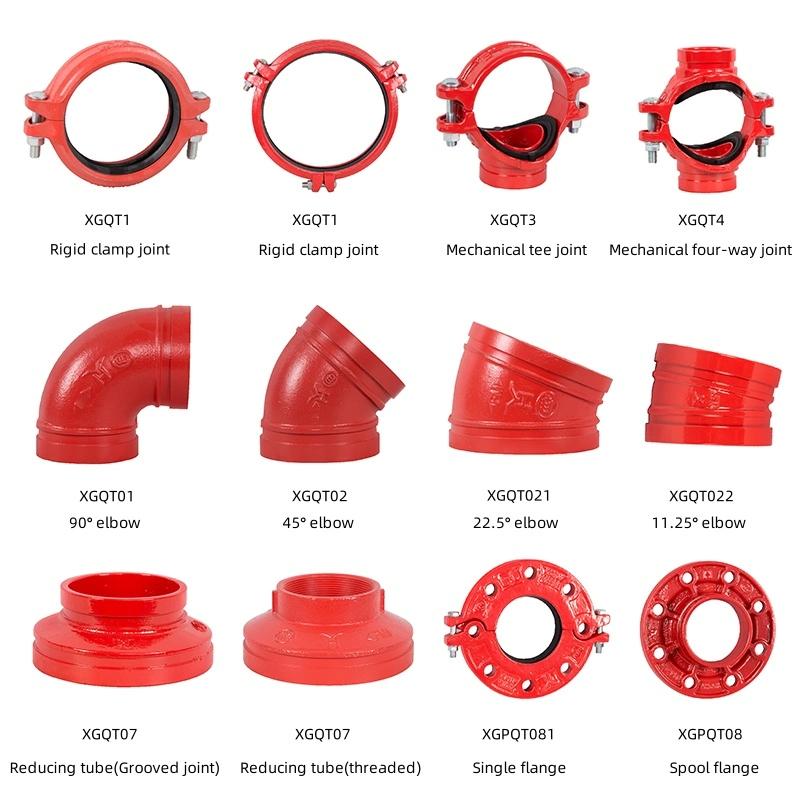

> Ductile Iron Grooved Coupling Pipe Elbow Fitting Flange Fire Fighting Tee Adaptor

Ductile Iron Grooved Coupling Pipe Elbow Fitting Flange Fire Fighting Tee Adaptor

Detail

Basic Info.

Model NO.

XGQT

Trademark

huhang

Origin

China

Production Capacity

50000PCS/Month

Product Description

1. Characteristics and description of grooved pipe joints and fittings

1)Fastspeed

There is no need to weld and re-galvanized, and the installation speed is more than 3 times faster than the flange connection pipe.

2)Janeeasy

It is lighter than the flange, the locking mechanical design is clever, the number of bolts is small, and there is no need to lock the hole.

3)Reliable

The clamp, washer and pipe end groove are pressed by the whole circle, and the pipe end tensile strength is large, the test pressure is 4.2MPa, the temperature is -30ºC~100ºC, and the vacuum degree is up to 0.08MPa; The washer is designed as type C, which can form a triple leakproof, the greater the pressure in the tube, the better the seal; Gaskets can be comfortably selected due to fluid medium, pipe andtemperature. (Figure 1)

5)Economic security

5)Economic security

The project budget is easy to save 20% of the total project cost compared with the flange connection; Construction does not require power, oxygen, open flame.

6)Zero pollution

RateBecause the original installation does not have welding slag and damage to the galvanized and plastic coating layer. Therefore, it can ensure that the pipeline is smooth. The connected pipeline, especially the fire sprinkler system, will not rust and block the equipment spray in the pipeline due to other connections.

7)Occupy less space

The flange installation space is 3:2 compared with the clamp joint.

The clamp joint and accessories can be installed first, and can be adjusted in any direction, Angle, and piping at will.

8)Easy maintenance Disassembly

washing and replacement only need to remove two clamps and four bolts, which is convenient for pipeline extension, replacement and rotation direction. Uniform wear. Figure 3)

Quality and inspection:

Quality and inspection:

Regular check on production line at each working procedure, and one special inspector inspecting the goods in random during the period time of production.regular performance check on finished goods.

Production step:

1.The raw materials are cast or forged and processed into semi-finished products.

2.Processing the semi-products in works shop

3.Assembling the goods

4.Testing the sealing in pressure and checking quality of the goods

5.Package

6.Delivery the goods on time

Package:

1.The pakage standard:inside PVC bag and small box and standard export carton

2.If you have any special requirements pakage,we can pakage as per your artworks.

Primary Competitive Advantages:

1) We have several years of experience in manufacturing various types of valves professionally.

2) Products are of good quality, with reasonable prices.

3) Our style:Promise must be kept and action must be prompt and fruitful.

Our business idea:All for customers and everything from innovation.The size standards can be customized according to your specific requirements. Please feel free to contact us for more details.

1)Fastspeed

There is no need to weld and re-galvanized, and the installation speed is more than 3 times faster than the flange connection pipe.

2)Janeeasy

It is lighter than the flange, the locking mechanical design is clever, the number of bolts is small, and there is no need to lock the hole.

3)Reliable

The clamp, washer and pipe end groove are pressed by the whole circle, and the pipe end tensile strength is large, the test pressure is 4.2MPa, the temperature is -30ºC~100ºC, and the vacuum degree is up to 0.08MPa; The washer is designed as type C, which can form a triple leakproof, the greater the pressure in the tube, the better the seal; Gaskets can be comfortably selected due to fluid medium, pipe andtemperature. (Figure 1)

4)Vibration isolation and absorption

Because there is a gap at the end of the tube, it can effectively separate the transmission of noise and vibration; The pipe is not affected by thermal expansion and cold contraction; Sealing gasket can also absorb noise and vibration.(Figure 2)

Because there is a gap at the end of the tube, it can effectively separate the transmission of noise and vibration; The pipe is not affected by thermal expansion and cold contraction; Sealing gasket can also absorb noise and vibration.(Figure 2)

The project budget is easy to save 20% of the total project cost compared with the flange connection; Construction does not require power, oxygen, open flame.

6)Zero pollution

RateBecause the original installation does not have welding slag and damage to the galvanized and plastic coating layer. Therefore, it can ensure that the pipeline is smooth. The connected pipeline, especially the fire sprinkler system, will not rust and block the equipment spray in the pipeline due to other connections.

7)Occupy less space

The flange installation space is 3:2 compared with the clamp joint.

The clamp joint and accessories can be installed first, and can be adjusted in any direction, Angle, and piping at will.

8)Easy maintenance Disassembly

washing and replacement only need to remove two clamps and four bolts, which is convenient for pipeline extension, replacement and rotation direction. Uniform wear. Figure 3)

2.groove type pipe joint and pipe fittings application field

Quality and inspection:

Quality and inspection:Regular check on production line at each working procedure, and one special inspector inspecting the goods in random during the period time of production.regular performance check on finished goods.

Production step:

1.The raw materials are cast or forged and processed into semi-finished products.

2.Processing the semi-products in works shop

3.Assembling the goods

4.Testing the sealing in pressure and checking quality of the goods

5.Package

6.Delivery the goods on time

Package:

1.The pakage standard:inside PVC bag and small box and standard export carton

2.If you have any special requirements pakage,we can pakage as per your artworks.

Primary Competitive Advantages:

1) We have several years of experience in manufacturing various types of valves professionally.

2) Products are of good quality, with reasonable prices.

3) Our style:Promise must be kept and action must be prompt and fruitful.

Our business idea:All for customers and everything from innovation.The size standards can be customized according to your specific requirements. Please feel free to contact us for more details.