High Quality Flow Control Digital Balancing Valve

Detail

Basic Info.

Product Description

1.Overview

SP45F and SP15F digital locking balancing valves are a type of adjustment valve with special digital locking functionality. They feature a direct current valve body structure, providing better flow characteristics and enabling the rational distribution of flow. These valves effectively address the issue of uneven temperature distribution in heating (air conditioning) systems. Moreover, they accurately adjust pressure drop and flow to enhance liquid flow in pipeline systems, achieving fluid balance and energy savings goals.

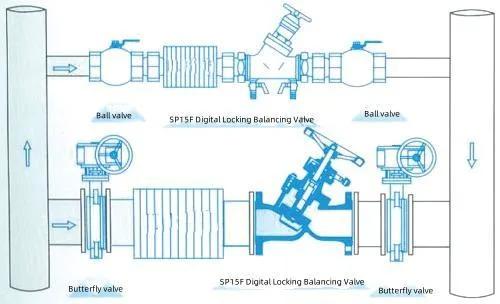

SP45F and SP15F digital locking balancing valves are equipped with an opening degree indicator, opening locking device, and a small pressure measuring valve for flow measurement. Simply install balancing valves of appropriate specifications in each branch and user entrance, and lock them after one-time adjustment using a dedicated intelligent instrument. This ensures that the total water volume of the system is controlled within a reasonable range, overcoming the unreasonable phenomenon of "large flow, small temperature difference". SP45F and SP15F balancing valves are ideal products for heating systems. They can be installed on both supply and return pipes, but it is generally recommended to install them on return pipes. Especially for high-temperature loops, for ease of adjustment, they should be installed on return pipes. Supply (return) pipes equipped with balancing valves do not need additional shut-off valves.

2.Product characteristics

This valve is a balancing valve, suitable for various liquid pipeline systems, and is a relatively ideal new type of energy-saving valve. The valve is equipped with calibrated digital display for intuitive adjustment to any position, and can be locked. The valve is mainly used in industrial and civil building heating pipeline systems. Currently, there are hydraulic imbalances in some pipeline systems, and balancing valves provide a means to solve this problem. They can accurately adjust the pressure drop and flow rate, thereby improving the liquid flow conditions in pipeline systems, and achieving the purpose of liquid balance and energy saving in pipeline systems. In the renovation of dual-pipe network projects, the application of this valve can still save energy and achieve good results.

3.main technical parameters

|

Nominal Pressure (MPa) |

Applicable temperature |

Body Test Pressure (MPa) |

Characteristic Curve |

Applicable medium |

Installation range |

| 1.0 | ≤120ºC | 2.5 |

Equal Percentage |

Water, oil and other non-corrosiveErosive liquid | Pipe network system trunk,branch trunk, indoor water supply trunk, branch risers andmultiple boilers |

| 1.6 | 1.4 |

4.Product standards

Design and manufacturing standard implementation BS7350-1990; Inspection test standard BS7350;

Flange connection standard GB/T17241.6-2008 "integral cast iron flange";

Structure length standard GB/T12221-05 "Metal valve structure length";

The wire connection standard is GB/ T7306.1-7306.2

5.The main parts material

6.The main connection size

The figure on the right is the flow characteristic curve of this kind of valve, and the factory produces valves with equal percentage characteristics. It can be seen from the graph that if the opening is given an equal rate of change, the rate of change of the flow is equal, which is characterized by a large flow rate when the opening is large, and a small flow rate when the opening is small. Most of the engineering is used when the flow is large, and the equal percentage valve is precisely suitable for this requirement. According to this feature, a certain flow rate can be freely set (quick opening valves and linear valves do not have this function) and when it is necessary to change, it can also know the change amount to achieve the ideal state.

7.The whole circle flow coefficient KV value table

8.Flow presetting (set the number of turns 2.5)

9.Transportation and storage

1)The valve after packing should not collide, dump, squeeze and be hit by rain and snow during transportation and storage.

2)The valve should be stored in a clean, dry, fireproof and well-ventilated place, and there should be no corrosive gases around;

3)The packed valve should be handled with pallets, light handling, forklift or crane can not directly act on the valve body.

4)Static balance valve in transportation and storage in the spool just leave the seat of the open state, strictly prohibited to close.

5)Static balance valve during transportation and storage, the valve seat or spool may be coated with lubricating oil, it is strictly prohibited to use alcohol, gasoline and other chemical solvents to scrub.

10.Installation

1)Static balancing valve before and after the valve must ensure that sufficient length of the branch pipe section to ensure the rated flow output;

2)Check the installation position of the static balance valve according to the drawing. It is recommended to install the static balance valve on the HVAC system return pipe. At the same time, check the pipeline water flow direction and install the static balance valve strictly in the direction of the water flow arrow on the valve body.

3)Before installing the static balance valve, clean the debris in the pipeline. It is forbidden to leave welding slag, branches, stones and other debris in the pipeline to avoid damage to the valve;

4)The welding of the pipe flange cannot cause excessive deformation, and the welding Angle does not affect the flatness of the sealing surface;

5) After the static balancing valve is installed, the valve should be fully opened so that the pipeline can be flushed repeatedly until it is clean. It is forbidden to close the valve repeatedly during pipeline flushing to avoid damage

6 )After the pipe is washed clean, the static balance valve should be switched on and off several times, and check whether the counter position is "zero" when it is closed. Before the valve leaves the factory, it has been strictly

tested, and the counter should be in the "zero" position when it is closed.To replace the corresponding parts,please contact the customer service department of Shanghai Airlines;

11.Debugging and maintenance

1 The debugging of the balance valve belongs to the system debugging. If the user has debugging, please contact the customer service department of Shanghai Airlines;

2 Balance valve is life balance design, so under normal conditions of long-term use maintenance free, no wearing parts;

3 After the balance valve has been used for several years, the rubber sealing parts may show signs of damage or aging, and the rubber seat is needed.

4 When the ambient temperature is below the freezing point in winter, please take anti-freezing measures to avoid freezing the valve body.

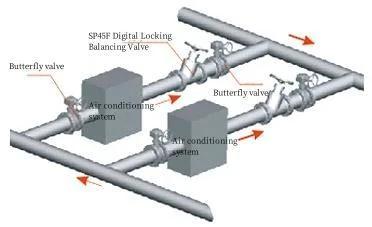

12.Typical installation diagram

Quality and inspection:

Quality and inspection:Regular check on production line at each working procedure, and one special inspector inspecting the goods in random during the period time of production.regular performance check on finished goods.

Production step:

1.The raw materials are cast or forged and processed into semi-finished products.

2.Processing the semi-products in works shop

3.Assembling the goods

4.Testing the sealing in pressure and checking quality of the goods

5.Package

6.Delivery the goods on time

Package:

1.The pakage standard:inside PVC bag and small box and standard export carton

2.If you have any special requirements pakage,we can pakage as per your artworks.

Primary Competitive Advantages:

1) We have several years of experience in manufacturing various types of valves professionally.

2) Products are of good quality, with reasonable prices.

3) Our style:Promise must be kept and action must be prompt and fruitful.

Our business idea:All for customers and everything from innovation.The size standards can be customized according to your specific requirements. Please feel free to contact us for more details.