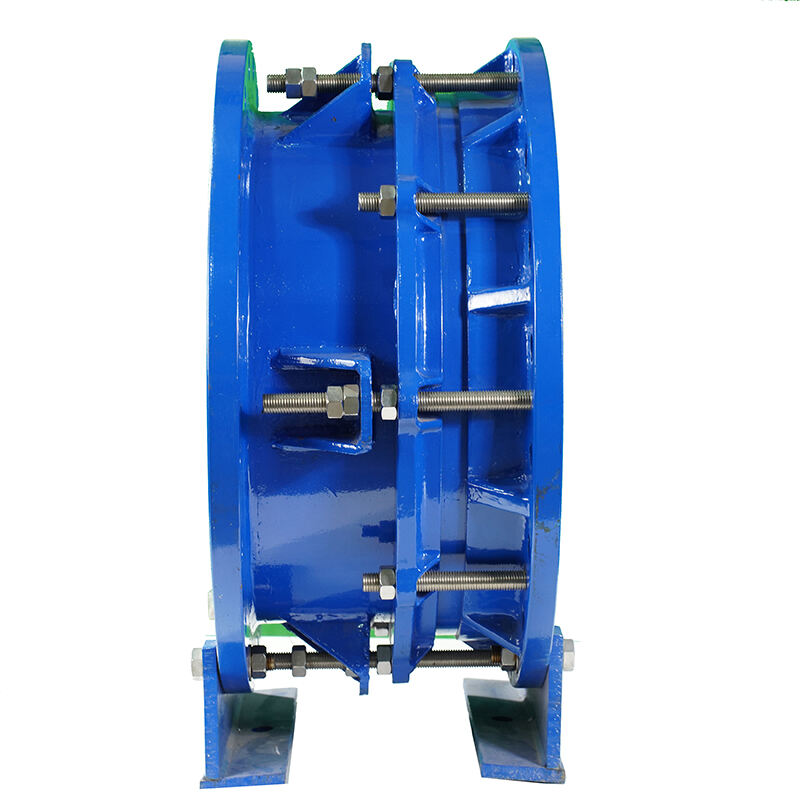

8 inch butterfly valve

The 8 inch butterfly valve represents a crucial component in fluid control systems, offering precise flow regulation in a compact and efficient design. This versatile valve features a disc-type closure mechanism that rotates on an axis perpendicular to the flow direction, enabling smooth transition between fully open and closed positions. Engineered with precision, the 8 inch size makes it particularly suitable for medium to large-scale industrial applications, including water treatment facilities, HVAC systems, and process manufacturing. The valve's construction typically incorporates high-grade materials such as ductile iron, stainless steel, or specialized alloys, ensuring durability and resistance to corrosion. Its quarter-turn operation mechanism allows for quick actuation, while the robust sealing system provides excellent shut-off capabilities. The design includes elastomer seats that ensure tight sealing and minimize leakage, even under varying pressure conditions. Modern 8 inch butterfly valves often feature advanced coating technologies that enhance their resistance to wear and chemical exposure, extending their operational lifespan. These valves can be equipped with manual, electric, or pneumatic actuators, offering flexibility in control options based on specific application requirements.