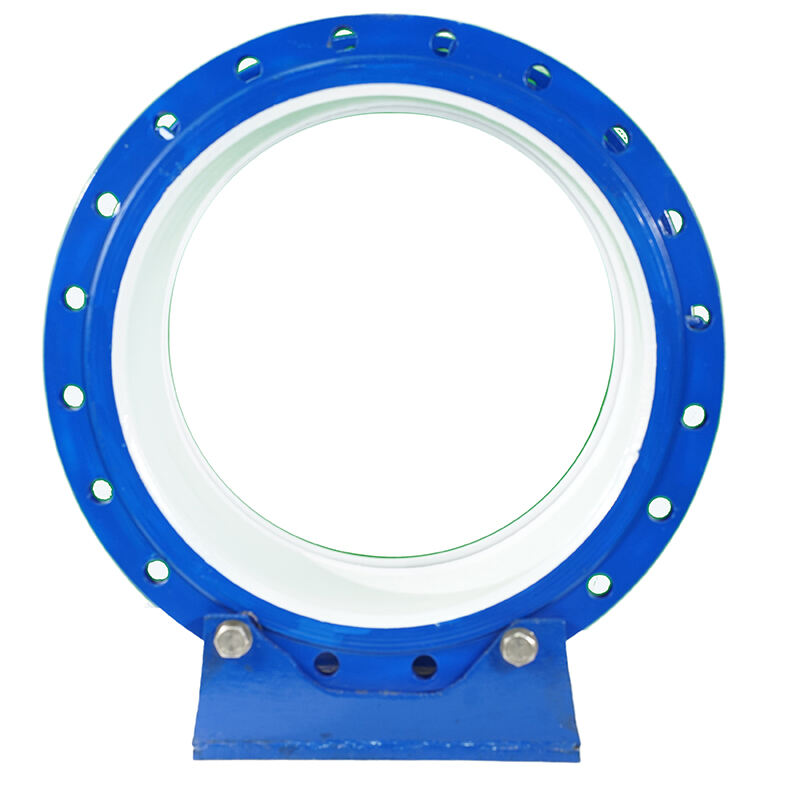

manual butterfly valve

A manual butterfly valve is a quarter-turn rotational flow control device that uses a disk to regulate fluid flow through a pipeline system. The valve's design centers around a metallic disk mounted on a rotating shaft, which can be manually operated to control flow rates with precision. When fully open, the disk rotates parallel to the flow, offering minimal resistance, while in the closed position, the disk sits perpendicular to the flow, creating a tight seal. These valves are engineered with various materials, including stainless steel, cast iron, and specialized alloys, making them suitable for diverse industrial applications. The manual operation mechanism typically features a hand lever or wheel that enables operators to achieve precise flow control. The valve's robust construction includes resilient seats, ensuring reliable sealing and extended service life. Notable for their compact design, these valves require minimal space for installation and maintenance, making them ideal for applications where space constraints are a concern. They excel in both on-off service and throttling applications, offering versatility across different industrial processes.