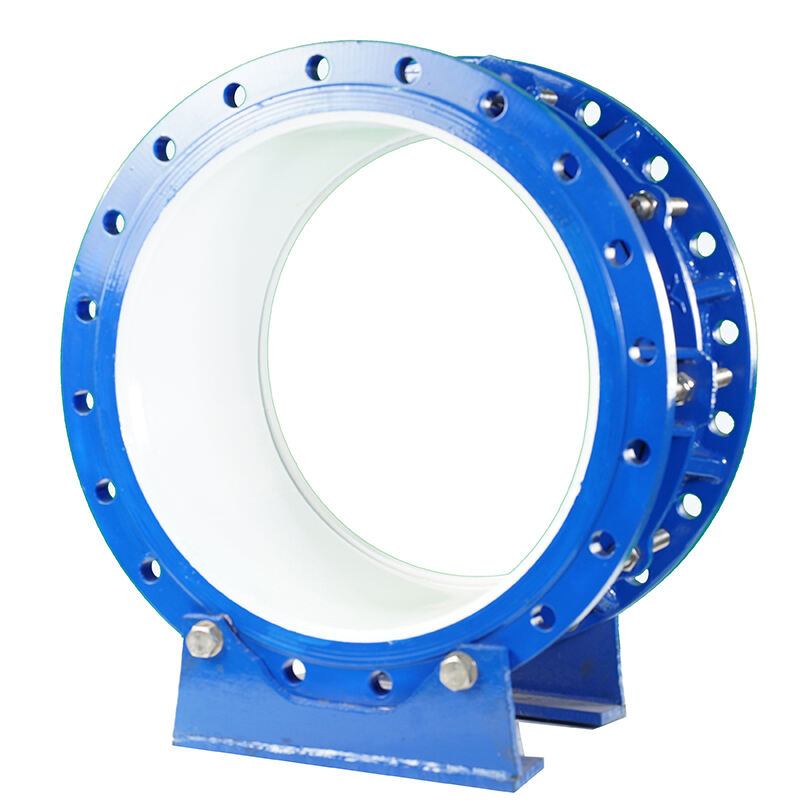

gear operated butterfly valve

A gear operated butterfly valve represents a crucial advancement in flow control technology, combining mechanical precision with operational reliability. This valve type consists of a disc mounted on a rotating shaft, controlled by a gear mechanism that enables precise flow regulation. The gear operation system provides mechanical advantage, allowing operators to control large valves with minimal effort while maintaining accurate positioning. The valve's design incorporates a gear box that converts rotational input into controlled disc movement, typically through a quarter-turn operation. These valves excel in applications requiring precise flow control, especially in large-diameter pipelines where manual operation would be impractical. The gear mechanism includes reduction gearing that provides smooth, gradual operation, preventing water hammer and ensuring consistent flow control. Industries such as water treatment, power generation, and chemical processing rely heavily on gear operated butterfly valves for their ability to handle high-pressure systems and various media types. The robust construction typically features ductile iron or cast steel bodies, with disc materials chosen based on specific application requirements. Modern designs often incorporate position indicators, mechanical stops, and lockable mechanisms for enhanced operational safety and control. The gear operator's self-locking feature prevents unauthorized operation and maintains the valve's position even under varying pressure conditions.