half inch ball valve manufacturer

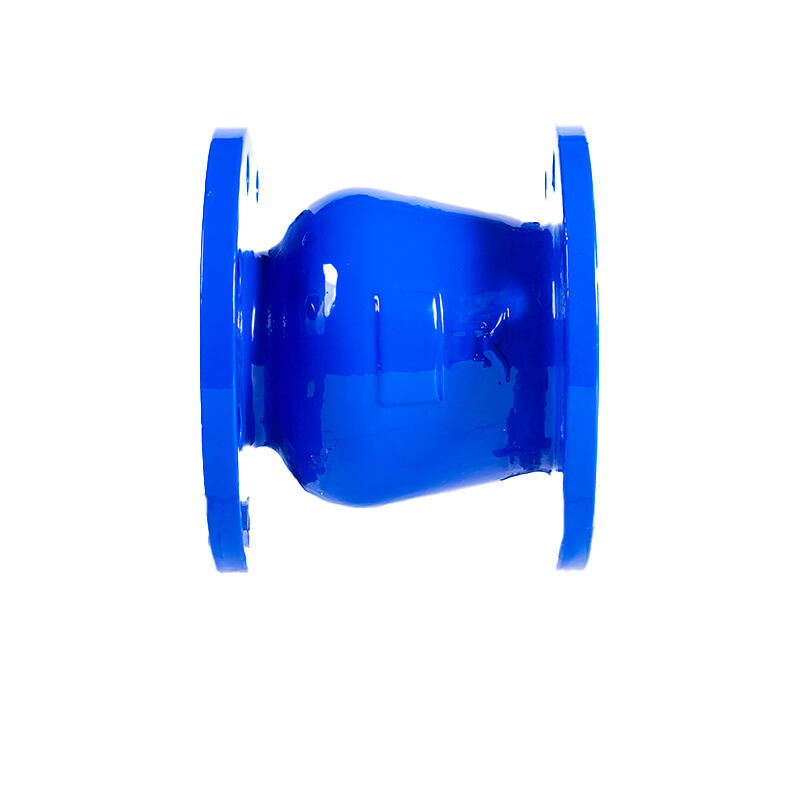

A half inch ball valve manufacturer specializes in producing precision-engineered flow control solutions that meet diverse industrial requirements. These manufacturers employ advanced manufacturing processes and quality control measures to create reliable, compact valves designed for optimal performance in various applications. The production facilities typically feature state-of-the-art equipment and testing capabilities, ensuring each valve meets strict industry standards. These manufacturers utilize high-grade materials such as stainless steel, brass, or specialized alloys to craft durable valves that withstand challenging operating conditions. The manufacturing process incorporates precision machining, sophisticated assembly techniques, and rigorous quality testing to ensure consistent product excellence. These facilities often maintain ISO certifications and adhere to international manufacturing standards, demonstrating their commitment to quality. The production line includes various valve configurations, including full port, reduced port, and multi-port designs, catering to different flow control needs. Advanced coating technologies and sealing solutions are implemented to enhance valve performance and longevity. The manufacturer's expertise extends to customization options, allowing them to meet specific customer requirements for pressure ratings, temperature resistance, and special applications.