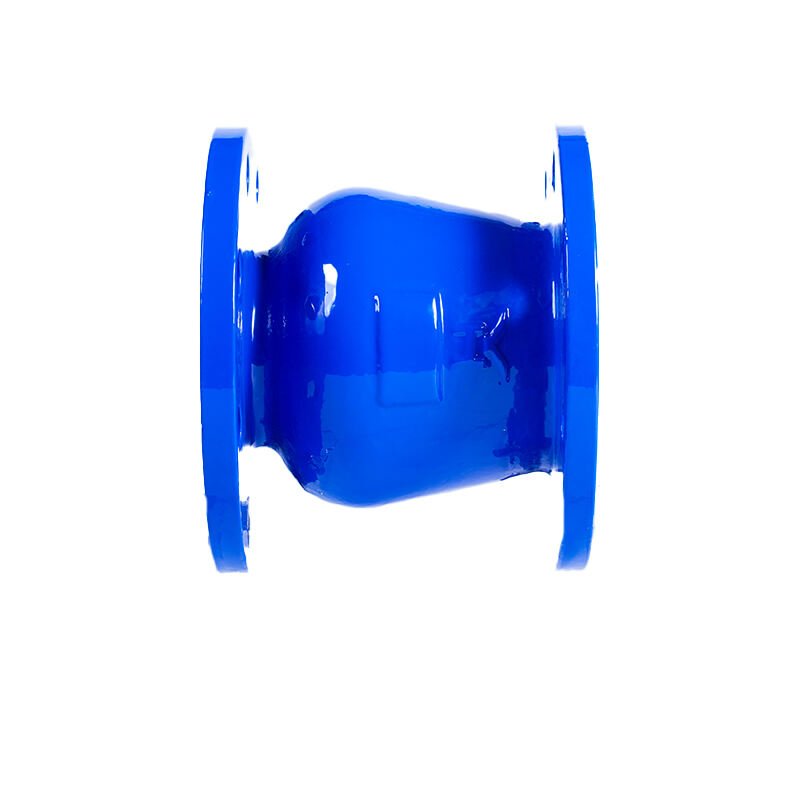

two way check valve manufacturer

A two way check valve manufacturer specializes in designing and producing high quality valves that control fluid flow in two directions within various systems. These manufacturers employ advanced engineering techniques and precision manufacturing processes to create reliable, durable valves that meet industry standards. Their products incorporate innovative design features such as dual disc mechanisms, spring assisted closure systems, and corrosion resistant materials. These valves are essential in preventing backflow and maintaining system integrity in numerous applications, including water treatment facilities, industrial processing plants, and HVAC systems. The manufacturing process involves rigorous quality control measures, from material selection to final testing, ensuring each valve meets strict performance criteria. Modern two way check valve manufacturers utilize computer aided design and automated production systems to maintain consistent quality while achieving high production efficiency. They typically offer a range of sizes and configurations to accommodate different pipe dimensions and operating conditions. Additionally, these manufacturers provide technical support and customization options to meet specific application requirements, backed by comprehensive warranty programs and after sales service.